General Motors hoped to leapfrog competitors like Ford, Volkswagen and Hyundai to become one of the largest EV manufacturers in the U.S. this year, lagging only behind Tesla, but problems at its first Ultium battery plant in Ohio have thrown that plan into chaos.

The automaker’s rollout of its initial battery-electric vehicles, notably the Cadillac Lyriq, has run well behind schedule, a number of issues contributing to the delays, various, sources tell Headlight.News. And the problems are going to take a while to resolve. GM this week announced a monthslong halt in production of its first commercial EV, the BrightDrop vans, coming out of its assembly plant in Ingersoll, Ontario.

“CAMI Assembly will take downtime beginning in October, due to previously announced delays in battery-module supply,” GM said in a statement. “Vehicle production is expected to resume in the spring of 2024, supported by the launch of CAMI’s new battery-module line which will have capacity to fully support BrightDrop production at CAMI and supplement EV production at other GM plants.”

Early EV entrant

GM was an early entrant into the electrified vehicle market, bringing out the Chevrolet Volt plug-in hybrid in 2011. It followed with one of the first long-range, all-electric models, the Chevy Bolt EV, in 2016. The current version of the Bolt will go out of production later this year — but it is scheduled to return in an all-new form, CEO Mary Barra said last month — using next-generation Ultium batteries set to power all future EVs.

The rollout of the first Ultium-powered models began with the GMC Hummer EV in 2022, followed shortly by the Cadillac Lyriq. Demand for both has been strong, GMC boss Duncan Aldred last week reporting about 90,000 reservations for the all-electric SUV. Cadillac officials have claimed similarly solid demand for the Lyriq.

Sales fall behind schedule

But actual deliveries for those and other GM EVs have been running well behind schedule, with only about 50,000 winding up in customer hands during the first half of this years, and an equal number expected to be delivered in the second half, according to spokesman Jim Cain.

The original goal, however, was closer to 400,000 for the full year, said Sam Abuelsamid, lead automotive analyst for Guidehouse Insights. That target, he noted, has been “pushed back at least six to nine months.”

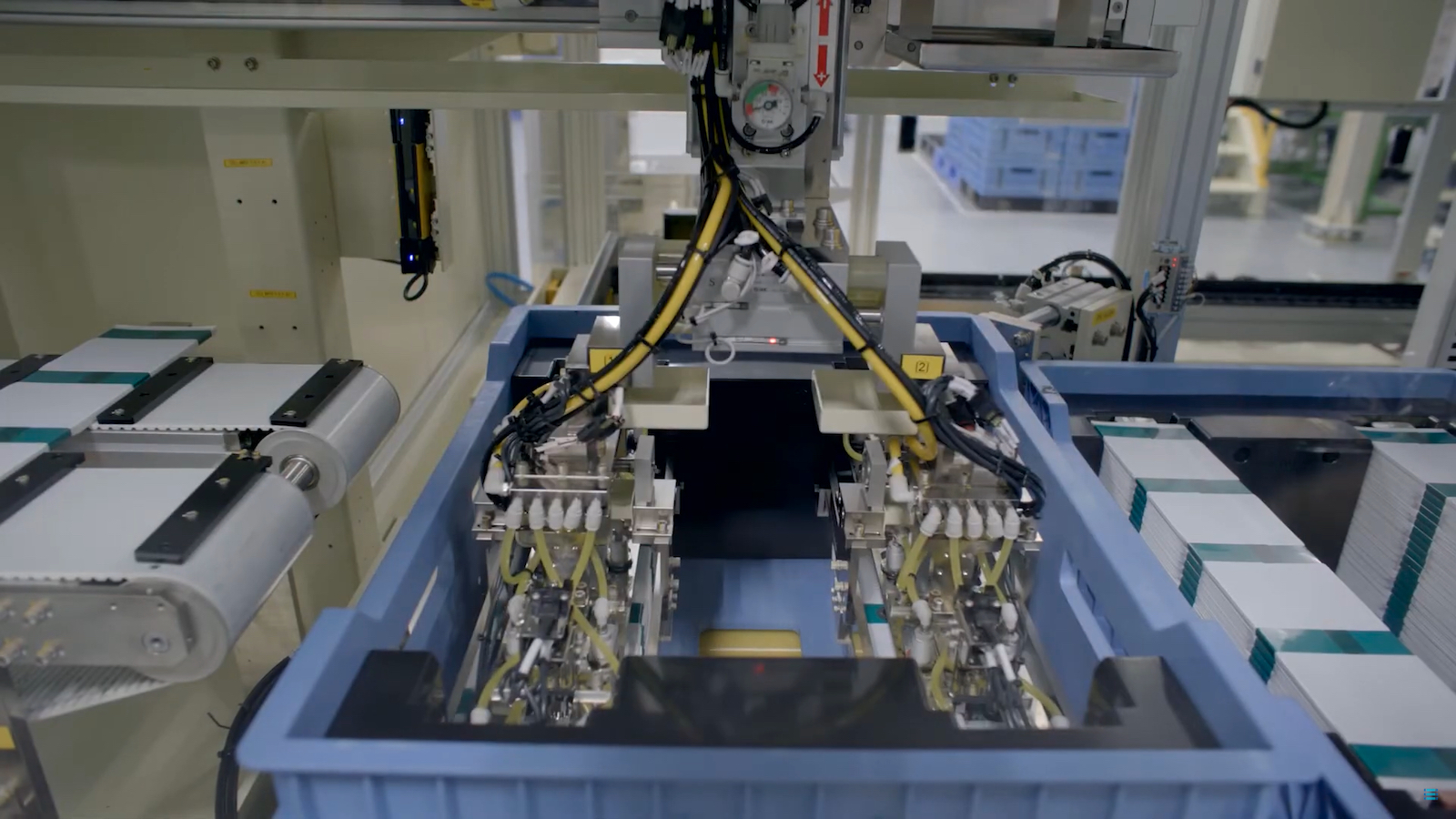

Production issues at the Ultium Cells plant in Ohio has slowed production of certain electric vehicles.

Trouble in Lordstown

The reason for the delays has been a matter of speculation for some time, but Headlight.News has uncovered some of the most serious. These include supply chain issues, starting with the semiconductor shortages that have broadly plagued the auto industry for several years, said a Cadillac official, asking not to be identified.

But the most serious problem involves the production system GM has put in place at its first Ultium plant in Lordstown, Ohio.

Faulty robotics

Essentially, there are three distinct steps in the production process. It starts with the manufacturing of individual battery cells. The next step is to load cells into modules. Those modules — in some vehicles there may be two dozen or more — are then assembled into the battery packs that typically ride underneath a vehicle’s load floor.

“Cell production is going great,” spokesman Cain acknowledged. But the issue involves the robotized hardware used “in the process of putting those cells into modules that can’t keep up.”

Specifically, said Abuelsamid, a key supplier of the robotic module assembly hardware has had trouble delivering enough working hardware to the Lordstown Ultium plant.

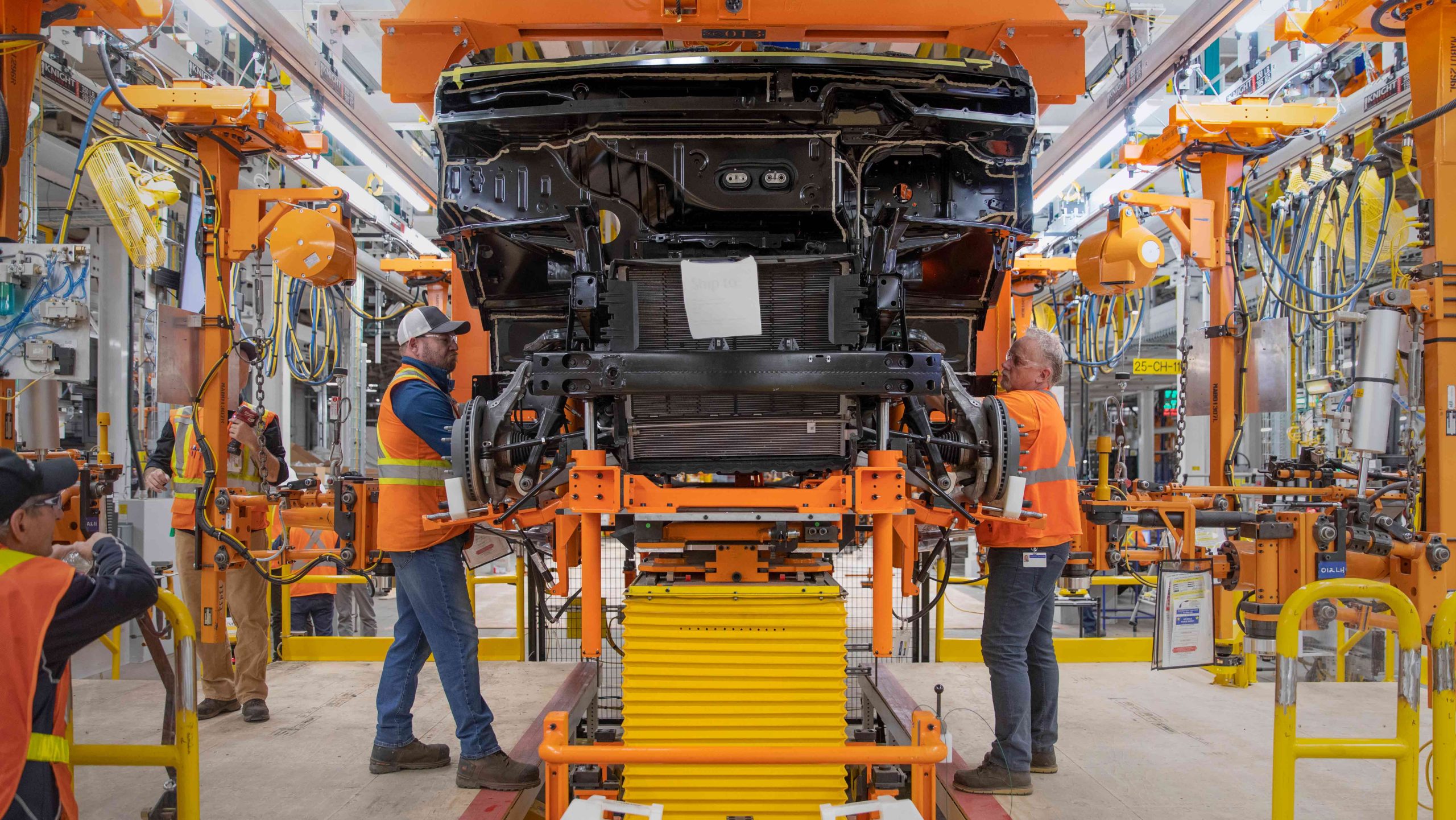

GM finds a temporary fix

In a temporary, stop-gap solution, GM has modified the production process. It is shipping batteries by the hundreds of thousands to each of its key EV assembly plants, using a makeshift system to stuff them into modules, and modules into packs.

While Cain wouldn’t go into details about the long term, Abuelsamid sees this as only “a short-term fix. I can’t imagine they want to use that long term. It requires more manual labor than what they original intended and they eventually have to find a solution that actually works and takes cost out of the system.”

Production accelerates

For now, the fix is helping speed up operations at three plants assembling retail EVs:

- Factory Zero, the GM line in Detroit producing, among other products, the Hummer EV;

- The operation in Ramos Arizpe, Mexico that is gearing up to start building Chevy’s Blazer EV and Equinox EV sport-utility vehicles;

- And the assembly complex in Spring Hill, Tennessee currently producing the Cadillac Lyriq. Next year, it will begin rolling out both the new Honda Prologue and Acura ZDX EVs.

Barra set to deliver an update

The challenge of getting the alternative system in place has led GM to put on hold production of BrightDrop vans, but it is expected to resume operation next spring.

“We are working on multiple fronts to put this behind us as quickly as possible, and things are improving,” Cain told Headlight.News. “For example, we have deployed teams from GM manufacturing engineering to work on site with our automation supplier”

GM CEO Barra is expected to further detail progress at the automaker’s EV plants during a third-quarter earnings call, said Cain.

0 Comments