With the UAW looking to represent the battery plants run by automakers, Stellantis revealed its plans to partner with Samsung SDI on a $3.2 billion facility in Kokomo, Indiana. It’ll be their second plant in the U.S. once completed.

Samsung SDI CEO Yoonho Choi (left) and Stellantis North America COO Mark Stewart sign the agreement to create the first JV gigafactory.

Stellantis is hoping the second time is the charm, partnering again with Samsung SDI on another battery gigafactory in Kokomo, Indiana with the new site costing $3.2 billion.

The pair’s first StarPlus Energy gigafactory, announced last year, is a $2.5 billion facility expected to be online in the first quarter of 2025. It’s expected to have a production capacity of 33 gigawatt hours (GWh). The new site is co-located in Kokomo and should produce 34 GWh of batteries.

The $3.2 billion plant will employ 1,400 people, bringing the total between the two sites to 2,800 and an investment of $6.3 billion. The second facility should begin operation in early 2027, officials said.

“Our battery ecosystem is the foundation of our electrification strategy, and our great partners Samsung SDI, the state of Indiana and the city of Kokomo have created a compelling case for locating our sixth gigafactory in Kokomo,” said Mark Stewart, Stellantis COO North America.

“The BEVs coming to our North America brands play an important role in our drive to offer clean, safe and affordable mobility for all and achieve the bold goal of carbon net zero by 2038.”

New members?

The two new battery gigafactories not only signal the company’s seriousness about its Dare Forward plan where 50% of its new vehicles sold will be battery-electric models, but also may represent a new pool of potential members for the UAW.

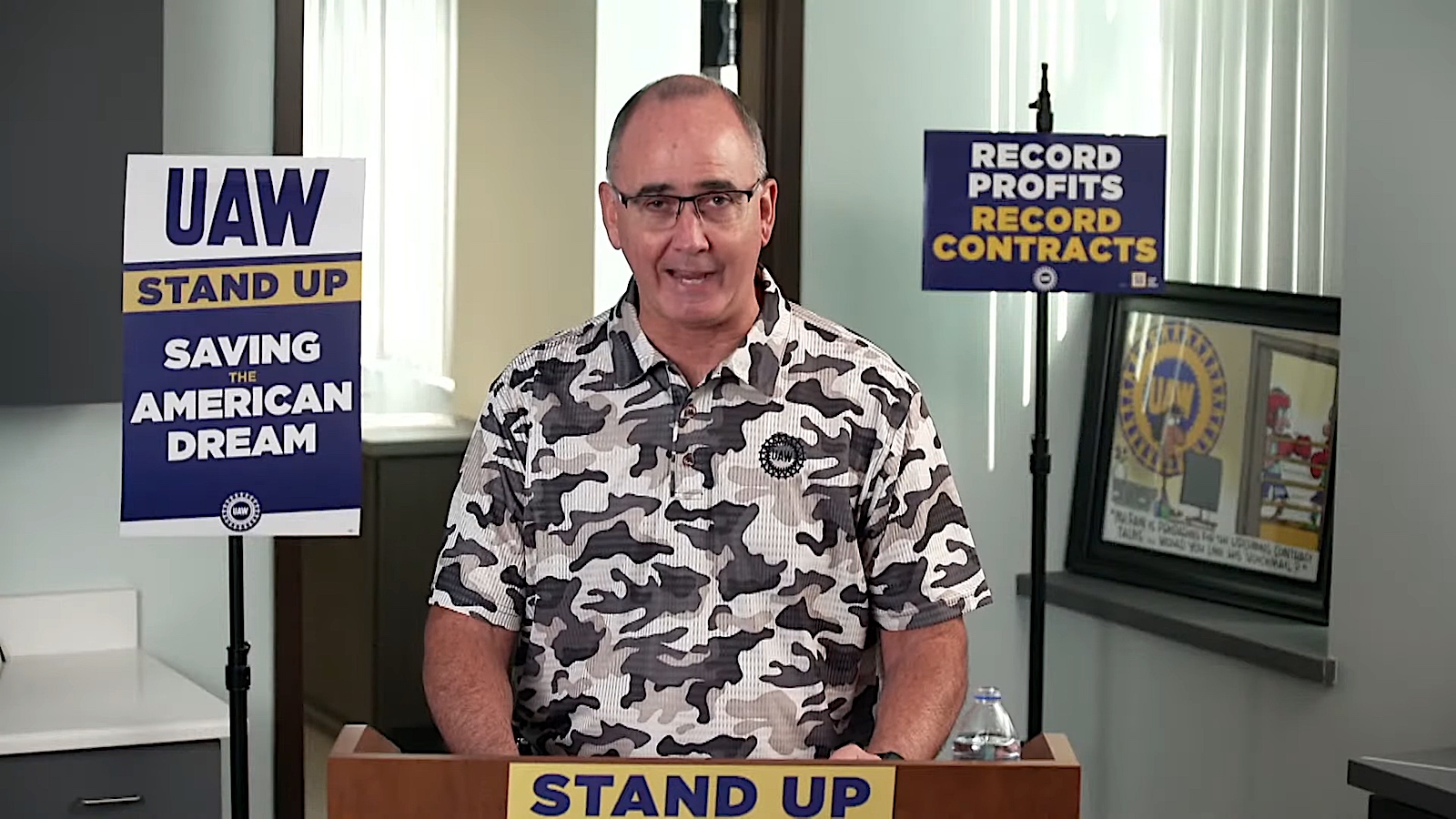

One of the goals set out by UAW President Shawn Fain has been to get the Detroit Three automakers to include the battery plants in the new master agreement. It secured a commitment from General Motors to do just that last week.

Ford hasn’t agreed to do the same, despite pressure from the union to do so. Ford CEO Jim Farley said the UAW is trying to use the battery plant issue to slow talks and get the company to relent.

“The UAW is holding the deal hostage over battery plants,” he said.

Let’s go down to Kokomo

The company appears to be making Kokomo an EV hub, announcing plans to invest $155 million in three plants to produce new electric drive modules (EDM) that will help power future electric vehicles assembled in North America. The EDM gearbox cover will be machined at the Kokomo Transmission Plant. Production is expected to start in the third quarter of 2024, following retooling.

The three Stellantis plants in Kokomo, Indiana are playing a roe in the company’s Dare Forward 2030.

Stellantis aims to have 50% of its sales be EVs by 2030. To make that happen, it plans to launch more than 25 BEVs in the U.S. by 2030 on four platforms. The Kokomo-built EDM will be integrated into vehicles designed on the STLA Large and STLA Frame platforms.

Stellantis has a history in the Indiana city with a casting plant and two transmission plants.

The 3.1 million square-foot Kokomo Transmission Plant employs nearly 2,100 people. It produces engine block castings, transmission components and handle transmission assembly for the Jeep Grand Cherokee, Wrangler and Gladiator, as well as the Chrysler 300, Dodge Charger, Dodge Challenger, Dodge Durango and Ram 1500.

The Indiana Transmission Plant, also in Kokomo, is 1.2 million square-foot plant with more than 1,700 workers. It handles transmissions for Ram trucks, Cummins Diesel and Heavy Duty, as well as the Jeep Cherokee, Jeep Renegade, Chrysler Pacifica and Ram ProMaster City.

Kokomo Casting employs about 1,100 people and is the world’s largest die-cast facility, the company says.

0 Comments