In 1927, the German director Fritz Lang’s legendary film, Metropolis, introduced the idea of humanoid robots. Now, nearly a century later, robots have become a common site on automotive assembly lines but look little like the Maschinenmensch Lang envisioned. Or they have so far. But as part of a new partnership with the California-based startup Figure, BMW is about to put the first humanoid robots to work on its assembly line in Spartanburg, South Carolina.

Automakers have been using robots inside their plants for decades, BMW’s looking to add a different type of machine to its South Carolina plant.

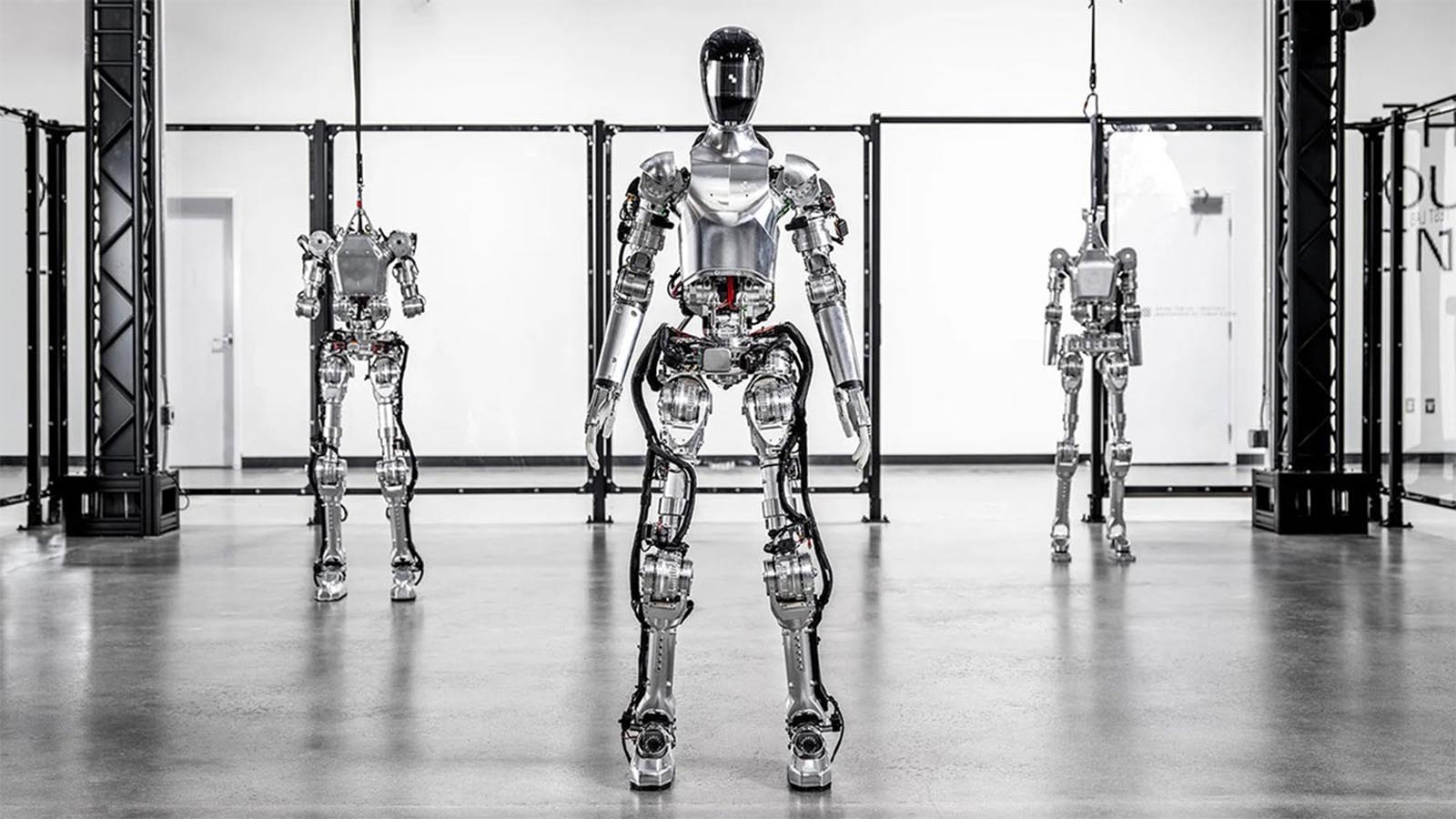

They look more like a Terminator than the humanoid robots in Fritz Lang’s Metropolis, but they’re a far cry from what automakers are today using on their assembly lines. And robot maker Figure announced Thursday it’s signed a deal with BMW to put its machines to work at the automaker’s sprawling assembly plant in Spartanburg, South Carolina.

Adopting the decidedly unsexy name, Figure 01, they’ll be put to work in the plant’s body shop, sheet metal operations and warehouses during the next two years.

BMW is the latest automaker to explore opportunities for human-like robots. Honda has trotted out a variety of updates to its ASIMO prototype since first introducing the machine — which looks like a human in a space suit — in 2000, Hyundai and General Motors have come up with their own concepts, GM sending one prototype for use on the International Space Station. And Tesla’s Optimus Gen 2 robot could find applications in the home as well as on the assembly line

More BMW news

- New Ride: BMW iX5 Hydrogen

- Q&A: Shaun Bugbee, BMW’s U.S. Operations Chief “We Have the Right EVs”

- First Look: 2024 BMW X2

Robots, robots everywhere.

The alliance with an automaker like BMW comes as no surprise. Assembling a vehicle can be grueling, even dangerous, work. Manufacturers have been rolling robots into their plants since the 1970s, the vast majority assigned to body shops to handle difficult tasks like welding — for which they’re particularly suited to repeat their tasks with great accuracy. They’ve also taken over in paint booths and are frequently used to move parts and other goods around a plant.

BMW is the latest automaker to explore opportunities for human-like robots. This one is dubbed Figure 01.

But those robots don’t look like humans. In body shops, they’re more like multiarmed octopi. Elsewhere, they’re likely to be more like self-motivated carts and lifts — such as the automated guided vehicles that are used at Ford’s Rouge Electric Vehicle Center to move partially assembled EVs from one station to the next.

Automakers have also begun using machines like Spot, developed by Boston Robotics, now a subsidiary of Hyundai. It’s a four-legged, dog-like robot that provides a variety of services, such as mapping out a factory floor using onboard lidar, a 3D laser technology.

Figure 1

There clearly are reasons why the robots already in use have adopted unique shapes for tasks like welding or moving car bodies along the line, there are plenty of reasons why the race is on to come up with even more humanoid robots, such as Figure 1. Factory workstations have traditionally been designed around what humans are best capable of doing. And those workstations are where the next generation of robots could prove most effective — without having to completely redesign our factories.

Figure 1 has similar proportions to a well-muscled human, including head, torso, legs and arms. But what particularly stands out is its hands. The goal was to come up with similar levels of dexterity to the flesh and blood workers it will operate alongside. Having legs and human-like feet increase their value, as well, as with humans making it easier to move the robots from one task to another.

“We have designed the robot to be safe next to humans. Working with BMW on automation in a manufacturing facility is a huge validator for us in the space,” Figure CEO Brett Adcock said in a statement announcing the commercial deal with BMW.

Training

Figure 1 robots will be like human workers in another way, tasked with learning on the job using artificial intelligence, as well as sensors in their artificial hands, cameras and other sensing technology.

Like more traditional robots, operators also will be able to preprogram Figure 1 on-site and remotely.

The company has not provided data on how many of its humanoid robots will be provided to BMW. For now, at least, the automaker is leasing, rather than purchasing the machines.

Figure 1 will face competition going forward from a variety of entrants into the field for more humanoid robots, including Tesla and Hyundai’s Boston Robotics — the latter company recently showing off the capabilities of its tool-fetching Atlas. Honda has yet to lay out specific manufacturing plans but is expected to also push to develop even more anthropomorphic versions of ASIMO.

Figure 1 raised $70 million in new investments in 2023 and is currently valued at $400 million, according to Parkway Venture, which led the latest round.

0 Comments