Even the most diehard EV fans wish for a next-generation battery-breakthrough, with most of the attention focused on solid-state batteries. Proponents claim they’ll deliver better range at lower costs, among other benefits. And now, Honda says, it’s bringing the technology closer to reality with the debut of a demonstration line meant to prove out the processes needed to launch mass production.

There’s nothing that today’s battery-electric vehicles need – other than improved range, faster charging and lower costs. Add, perhaps a reduced risk of fire and proponents believe EVs would finally send internal combustion engines off to the automotive rust heap.

All that’s needed is a better battery. Researchers around the world are working a variety of new technologies, from sodium-sulfur to aluminum-ion. But most of the attention – and investments – targets the solid-state batteries that are widely expected to go into production before the end of the decade.

At least, that’s the goal. But making that happen has been proving more difficult than proponents have hoped. But Honda thinks it’s narrowing in on the right formula and on Wednesday debuted a new solid-state demonstration production line at its main R&D center in Sakura City, Japan. It could be the key, the automaker said, to bring the technology “to market in the second half of the 2020s,” it said in a statement.

“The all-solid-state battery is an innovative technology that will be a game changer in this EV era,” said Keiji Otsu, the president of Honda R&D.

What are solid-state batteries?

If you’ve ever seen a leaky old battery you’re well aware that traditional chemistry uses liquid electrolytes, whether you’re talking lead-aid, alkaline or lithium-ion cells. That creates a variety of problems – everything from those leaks to the risk of fire.

Solid-state batteries, as the name implies, replace those wet electrolytes with solid materials, whether polymers, ceramics or other substances. (Halfway alternatives that may still use some gel-like electrolytes are also under development.)

On paper, at least, solid state batteries offer a variety of advantages over today’s batteries. They should be lighter and more energy dense. That would mean packing more electrons into a typical pack, even while reducing weight, substantially improving range. They’re expected to charge faster – possibly matching the speed at which a motorist can refill a gas tank. And, without those flammable electrolytes, that should sharply reduce the risk of a vehicle fire, a serious concern with today’s lithium-ion batteries.

Making EVs affordable

Then there’s cost.

Currently battery technology has come down almost tenfold in price over the past decade and now stands at somewhere around $100 per kilowatt-hour, depending upon the source and type of battery. When you’re talking about a vehicle with 10 kWh of cells, however, that still adds up to around $10,000 – batteries typically being the most expensive component in a modern EV. And that’s a key reason why today’s battery-electric vehicles cost thousands more than comparable gas models

Experts, such as the Boston Consulting Group and the Center for Automotive Research, estimate solid-state batteries could come down by as much as half. And, at $50-60 a kWh, they project, EVs would be as affordable – potentially even cheaper than those gas models.

More Battery News

- Dodge Will Test Solid-State Batteries with Charger EV

- Are Solid-State Batteries Just Vaporware?

- Polestar Bets on New Battery That Can Charge as Fast as You Can Fill Your Tank

What is Honda doing

Solid-state batteries look great on paper, and in the lab. Small cells appear to work. Scaling them up to automotive size is another matter entirely.

“For the purpose of establishing the mass production process for its all-solid-state batteries, Honda built this demonstration line that replicates processes required for the mass production,” the automaker said in a statement.

The demo line covers about 295,000 square feet and is meant to replicate what Honda believes a volume facility will look like. It uses a roll-pressing process expected to increase the density of the cells and make continuous production possible, more like today’s batteries. Ultimately, the company said, it aims to “significantly reduce the production time per cell,” a key challenge for volume production at an affordable cost.

The competition isn’t resting

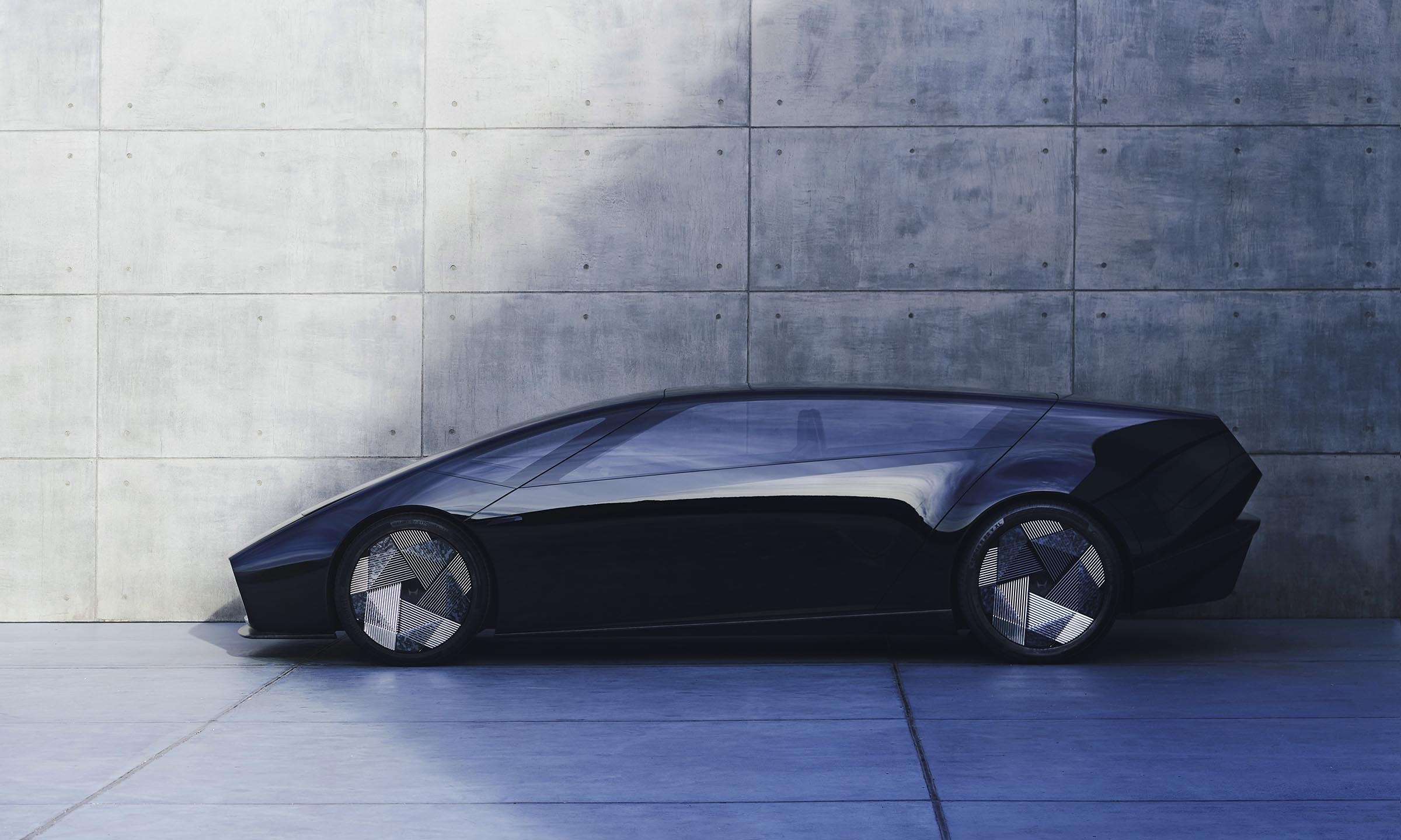

Honda could use solid-state cells to power up production of the “0 Series” EV concepts it unveiled at CES last January.

“We believe that advancement of batteries will be a driving force in the transformation of Honda,” said R&D chief Otsu. “Now, the start of operation of our demonstration production line for our all-solid-state batteries is in sight, and we can say that we have reached an important milestone for Honda and the country of Japan.”

Honda is by no means the only manufacturer betting on solid-state batteries to gain a leg up on the competition – and make EVs a more appealing alternative.

Toyota has confirmed a goal of bringing out some low-volume models using solid-state batteries before the end of the decade. And Dodge wants to road test the technology in its new Charger Daytona EV. A variety of other manufacturers have been testing the technology, whether in lab or on the road, including Nissan, Honda, BMW and others.

There are skeptics who question whether solid-state technology will ever make it into high-volume automotive production. Indeed, earlier this year, Ibex Investors partner Jeff Peters cautioned that “Investor interest in solid state batteries has waned. They are questioning whether the risk of solid state is worth it.” But, as Honda’s new project demonstrates, there are still plenty of companies betting the technology really will be the breakthrough the automotive industry needs.

0 Comments