The race is on to build a better EV, one delivering enhanced range and lower costs, among other things. Most of the attention has focused on next-generation batteries. But Hyundai is betting it has come up with a critical breakthrough by, quite literally, reinventing the wheel.

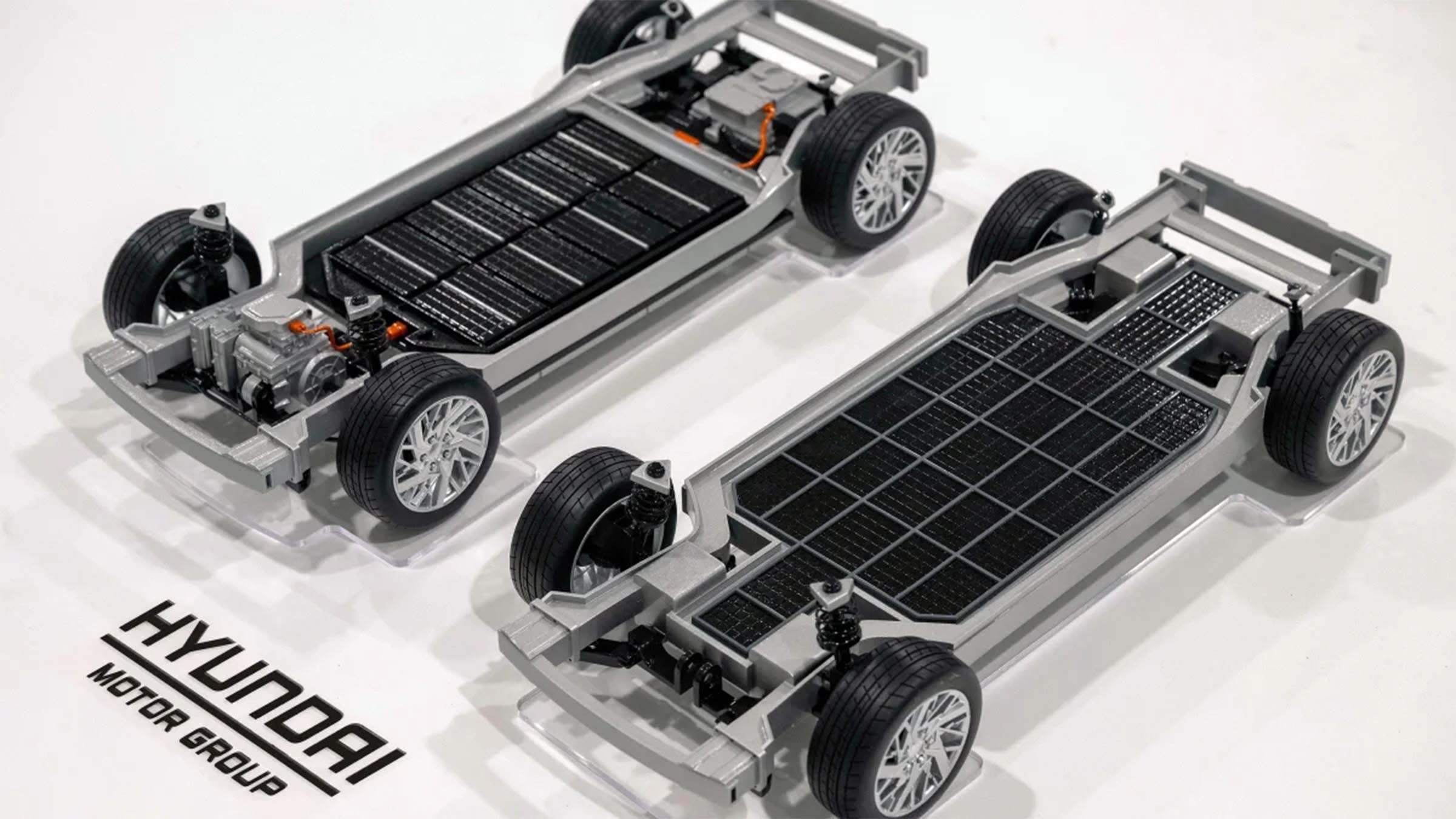

Using the Uni Wheel, the Hyundai EV platform on the right frees up space that could be used for more batteries.

No one quite knows who invented the wheel, or when, though history points towards Mesopotamia around 3,500 BCE. Over the millennia there’ve been a fair number of improvements, to the point where it’s a common trope that there’s “no reason to reinvent the wheel.”

Actually, maybe there is, in the hunt to come up with a better battery-electric vehicle. We’ve already seen some interesting developments. Lordstown Motors is one of several manufacturers adopting the hub motor which, as it suggests, mounts its motors inside the wheel, rather than on the axle.

Enter the Uni Wheel

Now, the Hyundai Motor Group has come up with another potential breakthrough it has dubbed the Universal Wheel Drive System. Uni Wheel for short.

Arguably, it’s not quite as revolutionary as a hub motor, but the South Korean carmaker claims it still can bring a number of significant improvements in terms of ride comfort and energy efficiency, among other things, while other saving space and weight.

The easiest way to understand what they’re doing is to look at the CV, or constant velocity, joints used in virtually every vehicle now on the road today.

They’re essential in sending power to the wheels when you have an independent axle set up, allowing wheels to both turn and move up and down as the vehicle bounces down the road.

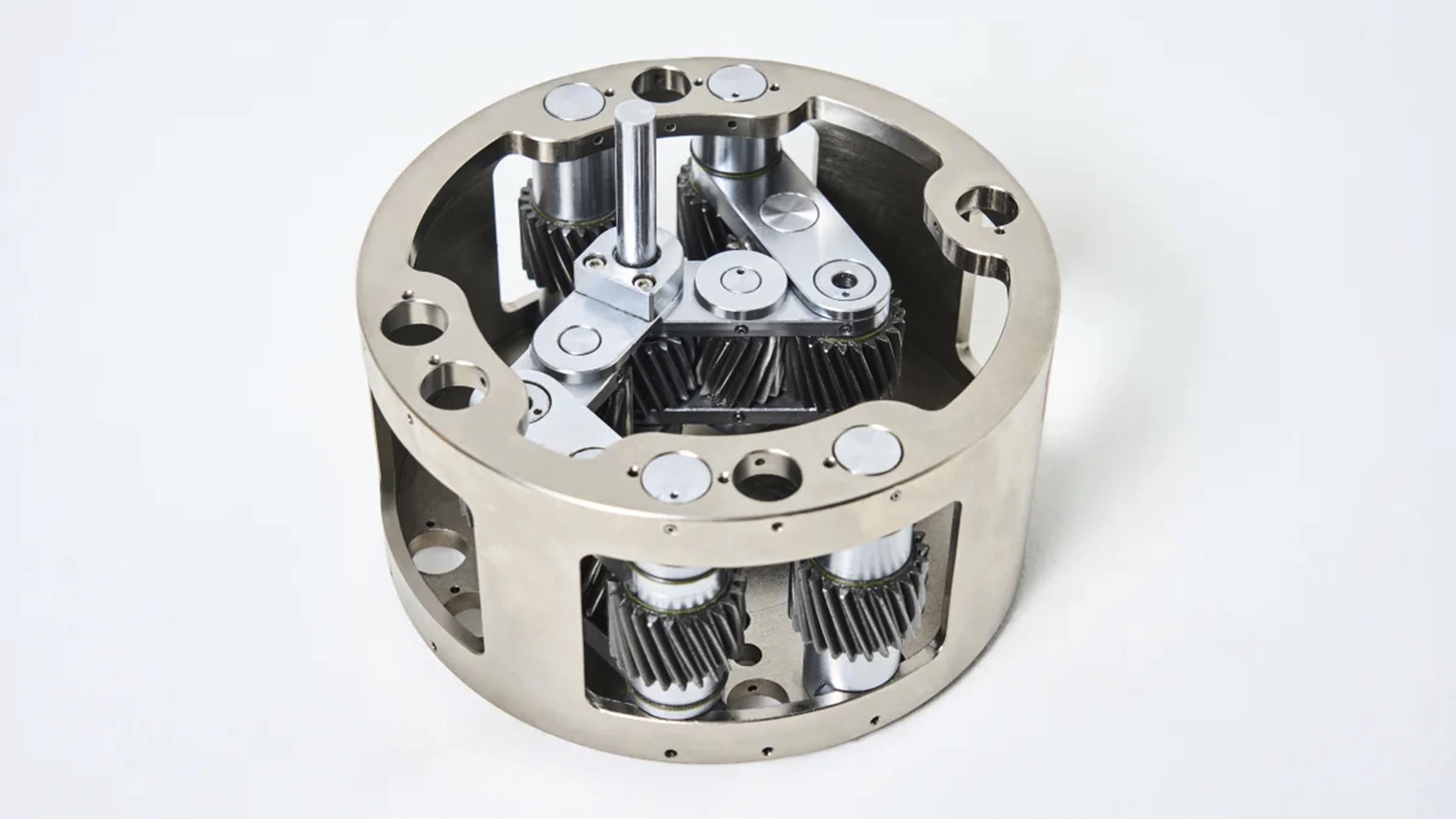

At its most essential, the Uni Wheel eliminates the standalone constant velocity joint and moves it inside the wheel.

More EV News:

- White House may make it easier to get EV tax credits

- Tesla finally delivers the first Cybertruck – but does it live up to expectations?

- GM, other automakers look to hybrids, plug-ins as EV sales growth slows

How it works

Here’s where we get a bit technical. As we see with today’s EVs, the motors remain on the axle, but the shaft sending power to the road connects to box-like contraption through a slot hiding a fairly complex series of planetary gears. In turn, that allows the Uni Wheel to bounce around as it does with a conventional CV joint system.

According to Hyundai, the approach not only saves weight and space but can solve some of the classic problems that CV joints face, such as premature wear on vehicles with extended wheel travel — something folks with off-road models like a Jeep Wrangler are well aware of.

Meanwhile, by freeing up space there could be room for, among other things, a bigger — as in longer range — battery pack.

Hyundai also claims the Uni Wheel could be used in other types of vehicles with two or three wheels, such as motorcycles and scooters.

The downside

There are potential downsides. Hyundai will have to prove Uni Wheel can stand up to the demands of not just everyday driving but the hefty gobs of torque electric motors can send to the wheels when you slam on the throttle. Recall that motors can make essentially all of their tire-spinning torque the moment they start spinning.

There’s also the issue of introducing all those meshing gears in the wheel, which could introduce a new source of noise that could irritate motorists and require new sound deadening solutions. And all those mechanicals add what’s known as unsprung weight to the wheel itself which will impact vehicle dynamics, such as ride harshness.

Finally, the Uni Wheel would have to be designed in a way that it could work with the other hardware used on an EV, such as blended brakes that combine conventional friction and regenerative braking systems.

Now what?

For the moment, Hyundai isn’t talking about what comes next. The automaker appears to be trying out the Uni Wheel system but it isn’t laying out a target for moving from concept to prototype to production.

Perhaps the single most important question will be how it impacts cost. The higher price tag for today’s EVs — compared to conventional gas models — is a serious issue. And if the Uni Wheel raises component and manufacturing costs without providing truly significant benefits it would likely remain a curiosity — and a lesson to engineers that they don’t need to keep trying to reinvent the wheel.

0 Comments