The damage wrought by Hurricane Helene could take months to calculate but it also could be felt worldwide. The floods that roared through the mountainous western part of North Carolina devastated one town, in particular, that is known for more than just its scenic views. It’s one of the world’s largest sources of the “high-purity quartz” needed to produce semiconductors. And it could touch off another major chip shortage in the months ahead.

Hurricane Helene has caused billions in damages in the Southeast U.S., notably in Florida’s Big Bend and the mountains of NC, GA and TN.

The population of little Spruce Pine, North Carolina is barely 2,200 and, except for the campers and hikers drawn to its scenic vistas, it might largely be misse

d among the many small hamlets in the mountainous western part of the state. But there’s another reason why Spruce Pine is suddenly in the news.

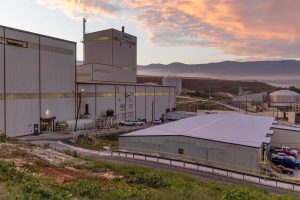

Located an hour from Asheville, the region’s biggest city, Spruce Pine happens to be the world’s largest source of the ultra-pure quartz that is used to produce semiconductor chips. Two companies currently mine the material for shipment all over the world but both operations are now, quite literally, under water, with no clear indication of when they might be able to start up again.

This comes at a particularly bad time for the semiconductor industry – and the countless other businesses relying on silicon chips, including the auto industry. Production has largely only just recovered from a chip shortage caused by the COVID pandemic. Now, a new shortage could be coming, and it would impact everything from smartphones to automobiles, appliances to high-tech weaponry.

The back story

Spruce Pines produced 70% of the world’s supply of high-purity quartz, or HPQ, needed for semiconductors and some other high-tech products/

Coming ashore at Florida’s Big Bend as a Category 4 storm, Hurricane Helene continued northeast, devastating a large region of the Southeast United States. It forced tens of thousands of residents to flee their homes and lay waste to communities across the mountainous regions of Georgia, North Carolina and Tennessee. Whole towns like Chimney Rock, NC have been washed away and others have been become unreachable, the storm devastating infrastructure like Interstate 40 needed to reach remote communities.

Among the communities still waterlogged is Spruce Pine, NC. The largest town in rural Mitchell County, it’s a mecca for hikers and campers, among other tourists. It’s also a place with an abundant supply of sand, some of which is used for the Augusta National Golf Course. But much of the sand found there falls into a unique category called “high-purity quartz.”. And it’s in high demand for the semiconductor industry, providing about 70% of the HPQ needed to produce chips and other electronic technologies.

“Inside nearly every cell phone and computer chip you’ll find quartz from Spruce Pine,” a manager for Quartz Corp. told the BBC in a 2019 interview.

But Quartz Corp. and the other company mining HPQ in Spruce Pine have both been forced to shut down as a result of the flooding. And that could prove devastating to global semiconductor manufacturing.

Under water

“As of September 26th, we have temporarily halted operations at the Spruce Pine facilities,” SCR-Sibelco, the Belgian-based company that also produces HPQ in Spruce Pine, said in a statement. It noted that its first task has been to locate and “confirm…the safety” of its employees, a task made difficult by the regional loss of power and disruption in landline and cellphone communications.

“Sibelco is actively collaborating with government agencies and third-party rescue and recovery operations to mitigate the impact of this event and to resume operations as soon as possible,” the company said in a statement, but it has yet to announce anything close to a firm timetable. It is unclear just how much damage its mines have suffered, and whether existing machinery might need repair or replacement.

As for Quartz Corp., it issued a statement saying, “We have no visibility on when (Spruce Pine operations) will restart. This is second order of priority. Our top priority remains the health and safety of our employees and their families.”

More Breaking News

- Buyer Beware: Flood-Damaged Used Cars Could Start Showing Up at Local Dealerships

- Automotive Brand Loyalty on the Rise

- New Vehicles at their Most Affordable in Three Years

A slow-rolling disaster in the making

While quartz is an extremely common material in the Earth’s crust, high-purity deposits are rare, with viable sources largely limited to the U.S., India and Brazil. There are lower-quality deposits in places like China but they are less desirable and harder to work with

“HPQ from Spruce Pine is, in a way, more critical and valuable because of its purity,” Jonnie Penn, an associate professor of AI ethics and society at the University of Cambridge, told Wired magazine. “This purity requirement matters most for advanced computing systems in areas like the military, healthcare, and quantum computing.”

Among the many yet-unanswered questions: how long will it take to get the Spruce Pine mines back in operation. But that’s just one challenge. Roads and highways across the region have been seriously damaged, bridges have been swept away. Parts of Interstate-40 were washed out. So, even when Quartz Corp. a

nd Sibelco do start back up it could be a challenge to deliver raw HPQ to customers, cautioned Sam Abuelsamid, principal auto analyst with Guidehouse Insights.

Another semiconductor shortage in the works?

BMW was one of the automakers temporarily deleting some high-tech features due to chip shortages during the pandemic.

The more immediate question is how much high-purity quartz is now in the pipeline and whether there’s enough of a buffer to carry manufacturers over until more of the raw material can be shipped?

That worries not only chip manufacturers but their end customers. The auto industry, in particular, suffered greatly during the COVID pandemic due to short chip supplies. That was a major reason why dealer inventories through much of 2022 and into 2023 fell as low as 1 million vehicles, about a third of normal. In some cases, automakers like Ford, General Motors, Volkswagen and Toyota were forced to idle assembly plants. In some cases, they deleted some vehicle features due to missing chips.

It could take some time before a clear picture emerges, and not just because it will take time to assess the damages to Spruce Pine operations.

“The supply chain is very long, from raw materials to finished products,” said Abuelsamid. As a result, if chip production is seriously restricted, “It will be months before that filters down into the auto industry.” But if the operations in Spruce Pine face a long-term shutdown, automakers and other chip users “potentially” face another major headache.

Now that you mention it, my cell phone coverge doesn’tseem to be as good since the storm. There seems to be gurgling sounds in the speaker.