When you’re posting nearly $20 billion in write-offs on your EV program it’s probably a good time to rethink what you’re doing. And that’s precisely why Ford Motor Co. launched the skunkworks Universal EV program designed to deliver “affordable,” long-range EVs that are also “fun to drive.” While the first version is still a year away, Headlight.News got a deep dive look at how the automaker plans to pull it off.

Ford Motor Co. had big plans for the battery-electric vehicle market when it rolled out the Mustang Mach-E, followed by the F-150 Lightning. And it had an assortment of other all-electric models under development, while launching plans to open the biggest manufacturing complex in its history, Blue Oval City near Memphis.

Things didn’t work out quite as planned. Ford last year scrapped plans for a 3-row electric SUV and, in December ended production of the Lightning. It also said Blue Oval City would be converted to production of conventional truck models – capping it all by posting a $19.5 billion write-off for the fourth quarter that resulted in an $8.2 billion loss for all of 2025.

Yet, even with the Trump administration ending federal tax credits, Ford isn’t ready to walk away from the EV market. Last August it announced a plan to rethink everything about the design, engineering and manufacturing of battery-electric vehicles, promising to launch an all-new line-up of “affordable,” long-range and “fun-to-drive” products set to reach showrooms in early 2027. At the time, it revealed the first will be a Maverick-sized pickup – but little more. Now, however, Headlight.News has gotten a chance to look a little further under the covers to see how the Universal EV crew plans to meet its lofty goals.

A New Approach

The new project gets a new logo retaining Ford’s classic blue color but swapping out the familiar oval shape.

When the F-150 Lightning debuted Ford officials noted that it differed only slightly from the conventional version of the best-selling full-size pickup. Sure, it swapped out its gas engine for an all-electric drivetrain, but you had to look closely to see the difference – notably a cross-grille lightbar and small “Lightning” badge on the back end. At the time, it seemed like an effective way to hold down costs. But it just added to the problems Ford faced getting beyond early adopters to win over mainstream buyers.

By this time a year ago it became obvious that things weren’t working out as planned. Ford scrapped several EV projects under development, including at least one 3-row SUV. And, as the year dragged on, it made the painful decision to not just scrap the slow-selling Lightning but to reverse course with Blue Oval City converted to a conventional light truck assembly operation. The automaker sold off one of its planned battery plants down South but, significantly, it decided to move forward with construction of the $3 billion Blue Oval Battery Plant in Marshall, Michigan.

That would be needed, it revealed in August, to supply cells for its new Universal EV project. Pulled together in an old warehouse in Long Beach, California, Ford tasked a small skunkworks team with rethinking absolutely everything taken as conventional wisdom when it comes to designing, engineering and manufacturing automobiles. And what they’ve come up with could be considered revolutionary – at least if they deliver on what we’ve now seen. No, the first Universal EV won’t lift off the ground and fly, but it still comes across as a revolutionary approach, even transforming the very manufacturing process first conceived by Ford Motor Co. founder Henry Ford.

The 40% Problem

When you set out to develop a new EV you have to start by recognizing the biggest problem right up front: the battery pack accounts for about 40% of your costs. And unless and until some radical, Star Trek-level alternative power source comes along, the challenge will be to come up with incremental solutions. The Universal EV team set out to address this in a variety of ways.

To start with, it’s opted to switch from familiar lithium-ion batteries, like those in the Lightning, to the lithium-iron-phosphate chemistry that will be used at the Blue Oval Battery Plant. While this yields a lower “energy density,” the amount of power that can be stored in a given sized cell, LFP batteries do have several welcome advantages: they’re cheaper, far less likely to suffer “thermal runaways” – read: fires – and don’t rely on costly metals like nickel and cobalt largely sourced from China.

To help offset their lower energy density, the Universal EV platform will load up its battery pack more densely – traditional EV packs wasting 50% or more of their space due to inefficient design, according to Sam Abuelsamid, lead auto analyst with Telemetry Research. Ford approached this like “a puzzle,” explained Universal EV project leader Alan Clarke. “We’re trying to fit the most cells possible inside the pack.”

Meanwhile, the pack becomes an integral part of the platform’s basic structure, further reducing mass.

More Ford News

- Ford Reports $8.2B Loss for 2025

- Ford Worker Suspended After Confrontation With Trump

- Big Year Ahead: Ford Racing Reveals F1 Racer, Le Mans Hypercar

Mass is the enemy

Meanwhile, the pack becomes an integral part of the platform’s basic structure, further reducing the vehicle’s weight. Mass is one of the big enemies of efficiency. The reality is that today’s EVs typically weigh hundreds, even thousands of pounds more than comparable gas models. And for each additional pound you need a bigger battery pack to get it moving; a vicious cycle.

So, Ford set up a series of “bounties,” aimed at motivating the Universal EV team to come up with creative solutions. In some cases, said Clarke, it accepted the use of more expensive parts and components if they could reduce mass. All the better if they could combine two functions into one. A case in point: sharing some of the components of the high-voltage DC and lower-voltage AC onboard chargers.

Another major breakthrough actually isn’t a Ford first. Tesla came up with the idea of using “megacastings” to replace large numbers of individual steel chassis components. Ford calls its approach “unicastings.” Whatever name you prefer, the all-electric pickup will replace the 146 separate steel parts in a Maverick’s front and rear chassis structure with just two huge aluminum castings, noted Vlad Bogachuk, who oversees vehicle structure efforts. That has a number of advantages, starting with mass – which is “one of the biggest efficiency robbers” in any vehicle. The unicastings are 27% lighter than the collective parts they replace, while eliminating 27% of the fasteners that otherwise would be needed.

Hard wired

In some cases, the Ford team found ways to both cut costs and slash mass.

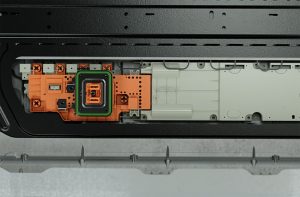

Universal EVs will use a completely new electrical system and a number of new digital components, including an engine control computer replacing what Clarke says were “hundreds” of parts with a single, flexible, multi-layered circuit board. It’s also migrating from a “distributed” to a “zonal” electrical architecture.

Modern vehicles scatter dozens, sometimes hundreds, of microprocessors around the vehicle to operate everything from seat heaters to the sensors used for advanced driver assistance systems. Instead, Universal EVs will consolidate that down to five centralized processing systems. And it will use an “E-box” to oversee everything, a system constantly monitoring how the vehicle operates and adjusting things on the fly, as necessary.

One of the benefits? You don’t need nearly as much costly copper in your wiring harness. Compared to some of Ford’s earlier EVs, the new electrical architecture will require about 4,000 feet less copper wire, here shaving another 22 pounds of range-stealing mass. Less money spent on that metal, less money spent on a downsized battery pack.

Cheating the Wind

Mass isn’t the only enemy. Pushing a vehicle through the wind requires a lot of energy, especially at highway speeds. So, reducing drag will be an essential step in all future Universal EV products. In some cases, even tiny revisions can have a big impact, stressed Saleem Merkt, Universal EV aerodynamic lead.

With the upcoming pickup, the roofline was lowered by a single millimeter, yet that improved aero efficiency enough to save about $1.30 in battery costs, Merkt boasted. The revised roof also routed air over the normally turbulent truck cargo bed so, “To the air, it’s no longer a pickup.” And there were additional savings from using smaller mirrors and a carefully designed underbody shield

Add it all up and you get lower costs and longer range, said Merkt. “If the same battery were married to the aerodynamics of the most aerodynamically efficient midsize gas truck in the U.S. we believe our new truck would have 50 miles, or 15% more range.” And, at highway speeds, where drag increases exponentially, the data shows a 30% improvement. This allowed Ford to downsize the battery a bit more, even while retaining a target range of at least 300 miles, saving about $100 in parts costs in the process.

Rethinking Henry Ford’s assembly line

True, there’ve been plenty of updates over the years to improve ergonomics and efficiency. But the automotive assembly line found in even today’s most sophisticated plants haven’t changed all that much in the 112 years since Henry Ford switched on the very first at the old Highland Park Assembly Plant making the Model T.

Ford ultimately will invest about $2 billion to transform its old Louisville Assembly Plant to build new Universal EVs. It’s not just to add more automation – in some instances, in fact, there’ll be fewer robots, thanks to breakthroughs like Ford’s first use of unicastings. Much of that money will go to completely redesigning the way vehicles roll down the Kentucky plant’s line. Make that three adjacent sub-assembly lines, one for the front of the vehicle, one for the rear, a third for the battery pack. Much like making a sandwich, those three pieces will be married together near the end of the line.

The savings will be measured in lower production costs and faster operations, Ford said when it first announced the Universal EV program, the automaker estimating it will be able to roll out new vehicles 40% faster than on a traditional assembly line.

Will it pay off

There’s no question Ford had to come up with something radically different, rather than just trying to fix some of its earlier mistakes. We’ve all been reminded what Albert Einstein said about doing the same thing over and over, expecting different results.

Whether the Universal EV team really has found the better, er, four-wheeled mousetrap is uncertain. It looks great on paper, and in what we’ve seen so far. It remains to be seen if it all will come together in practice.

And skeptics have questioned the decision to launch the program with a compact pickup, rather than a 2- or 3-row SUV. Hang tight, says Ford, those are coming.

The automaker has yet to release pertinent details. We know a version of the initial truck will deliver “over” 300 miles range, while project leader Clarke has advised there will be a lower-range, lower cost battery option, as well. We don’t yet know power and torque specs but it’s assumed there will be both 2- and 4-wheel-drive packages. As for pricing, Ford has suggested it will start at under $30,000, which will position the truck well in a market increasingly obsessed with “affordability.”

From a business standpoint, hitting Universal EV targets will be critical for Ford. CEO Jim Farley confirmed this month his company expects to continue losing money on its battery-electric operations through 2029, about when the new EV plant should be running nearer capacity. And, should demand exceed current expectations, we could see Ford tool up other lines to handle the assortment of different body styles the automaker is promising. We should get more insight by around this time next year.

0 Comments