Ford’s secret “skunkworks” program aimed at developing “a new generation” of affordable – and profitable – EVs will operate out of a new headquarters in Long Beach, California, not far from an old factory company founder Henry Ford set up 94 years ago to build the automaker’s Model A.

Ford announced a new EV skunkworks program that will attempt to create a new generation of small affordable EV vehicles.

Nearly a century ago, Ford Motor set up a factory in Long Beach, California to produce the then-new Model A, the successor to the automaker’s legendary Model T. The “Tin Lizzy,” as it had come to be known, had grown old and out of date, allowing General Motors to knock Ford off its throne as the best-selling carmaker in the world. The Model A was the product that helped Ford fight back.

Ford faces a new challenge today. While it is the second best-selling brand in the emerging EV market, it faces a growing assortment of competitors intent on undercutting Ford in terms of both production costs and retail pricing.

That led the Detroit automaker’s CEO Jim Farley to set up a new “skunkworks” program to secretly develop what spokesperson Emma Bergg described as “a new generation of small, affordable vehicles.” It turns out Ford is lifting a page from the past and again setting up shop in Long Beach.

The “mothership”

Models like the Ford GT and the Mustang Mach-E are two recent examples of products being developed outside the Ford “mothership” in Dearborn.

Over the years, Ford has developed some of its most important and intriguing products “working away from the Ford mothership,” the company’s well-entrenched product development operations back in Detroit, Farley explained earlier this year.

That includes exotic vehicles like the Ford GT supercar. But the goal of this project is to come up with vehicles even more mainstream than Ford’s current battery-electric vehicles, the Mustang Mach-E and F-150 Lightning.

While those have generated reasonable sales, positioning Ford just behind Tesla in the EV market, they’re still relatively expensive. And that is one of the key obstacles to broader EV acceptance, according to observers like John Murphy, the lead auto analyst at Bank of America Research.

Driving down costs

A key goal of Ford’s skunkworks program is to drive down the cost of EVs with current models like the F-150 Lightning being out of reach for some consumers.

The typical EV sold so far this year has cost close to $60,000, data from Kelley Blue Book shows, about $10,000 more than comparable vehicles using internal combustion engines. Even after recent price cuts, the lowest-cost Mach-E comes in at $41,890. The goal for most manufacturers is to start delivering EVs starting at or under $30,000. Stellantis CEO Carlos Tavares this month confirmed plans for a new Jeep that will drop as low as $25,000 – after factoring in federal tax credits.

Ford hasn’t announced a formal price target but is believed to be developing a similar strategy.

More Ford News

- First Drive: 2024 Ford Maverick Hybrid — The Most Fuel Efficient Pickup You Can Buy

- Ford CEO Doesn’t Rule Out Mustang Sedan in Interview, Hybrid Still In Play Too

- Ford CEO Farley Reveals “Skunkworks” Program Developing Low-Cost EV

California dreaming

Long Beach will play a key role in Ford’s attempt to bring more EV engineers under its corporate umbrella.

To come up with competitive EVs, Ford first has to ensure it has the development team. And, unlike past product programs, where most of the work involved mechanical engineers, it now has to tap into the pool for software specialists, putting it up against tech players like Google and Apple. It’s betting it can do so by setting up shop closer to the heart of the tech world. In California.

The goal is to bring in “some of the best EV engineers in the world,” said Farley.

“Long Beach is a key part of our broader strategy to attract top talent to develop future vehicles and experiences for our customers,” Doug Field, Ford’s chief EV, digital and design officer, said in a statement.

The reality is that the automaker already has operations in the Golden State, its Ford Advanced Electric Vehicle Team headquartered in Irvine. The new operations will be substantially larger and better funded.

Returning to Long Beach

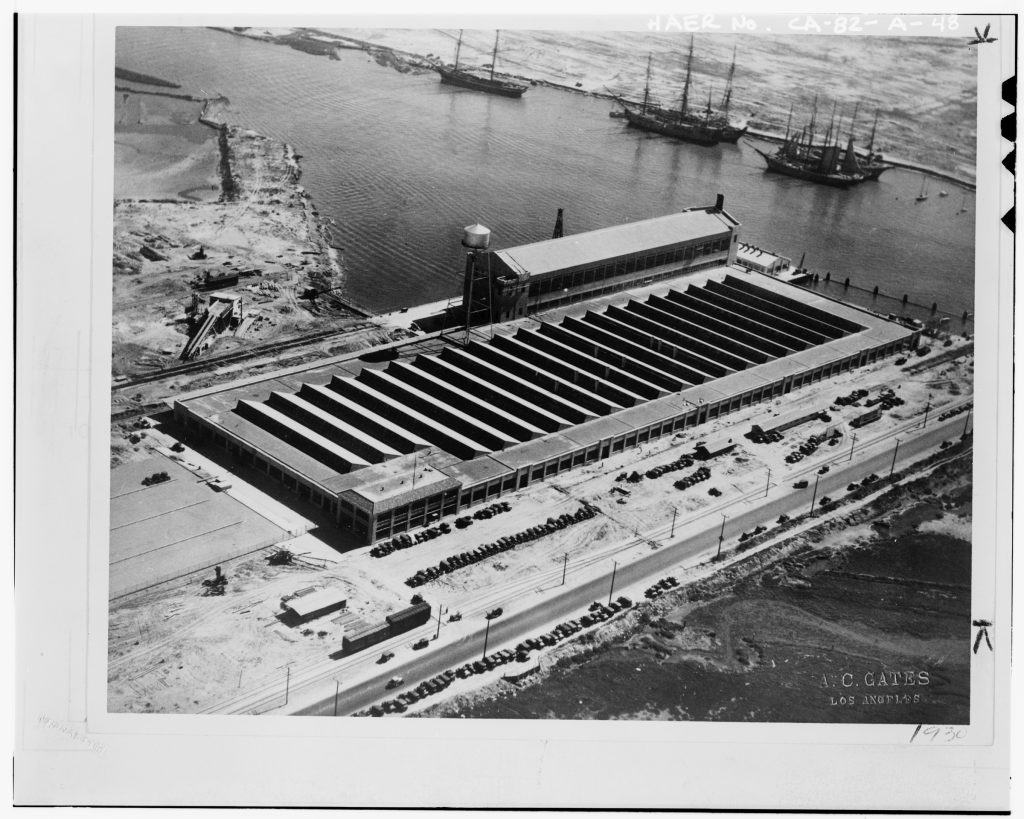

Ford’s newest Long Beach location follows up on the old Long Beach assembly plant which closed in 1958.

Though it hasn’t been there in a number of years, the automaker has long ties to the Los Angeles suburb.

Ford set up an assembly plant near Terminal Island, near the huge Port of Long Beach, back in 1930. At peak, the factory employed almost 2,000 hourly workers and churned out over a thousand of the Model A cars that replaced the original Model T each week.

That factory closed, however, in 1958, however, Ford set up a larger facility nearby. That plant in Pico Rivera was itself shut down back in the 1980s when virtually all automotive assembly operations closed down in California.

The Long Beach operation will help “create a hub for the development of advanced electric vehicle technologies and products” said Doug Field, who is heading Ford’s EV operations. But it won’t be the only place that work is underway. Ford this month opened up a major new technology center in Detroit, headquartered out of the newly restored Michigan Central Train Station in the city’s Corktown neighborhood. It will focus on a variety of advanced technologies, including autonomous vehicles, as well as EVs.

I watched the June 28th NBC interview with CEO Jim Farley. Interesting takes. Ever thought that new design directions can help implement everything that carmakers as well as many consumers are looking for: afFORDable electrive drive, improved safety, even advanced driv er assist? The central theme should be to aim beyond what Tesla is doing.

There’s no question that automakers like Ford cannot succeed if they only want to be followers — even fast followers. They have to aim for being the ones setting benchmarks.

Paul A. Eisenstein

New design directions (after all, there’s more to Personal Mobility than selling cars as we know them today) can help implement what automakers and many consumers are looking for: affordable electric drive, safety, Fahrvergnügen, even more advanced levels of driver assist.